High-temperature Ndfeb Magnet: Magnetic material with excellent performance and wide application

Publish Time: 2024-08-07

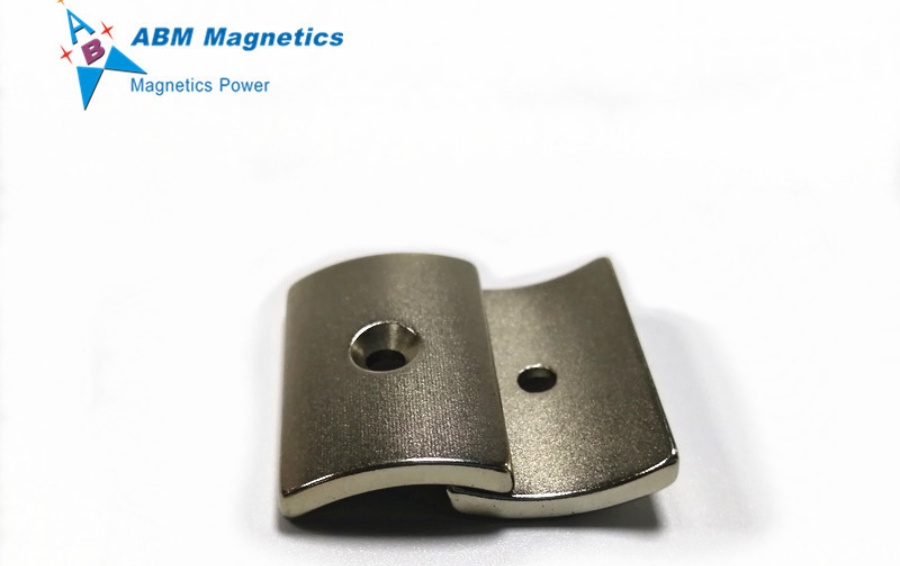

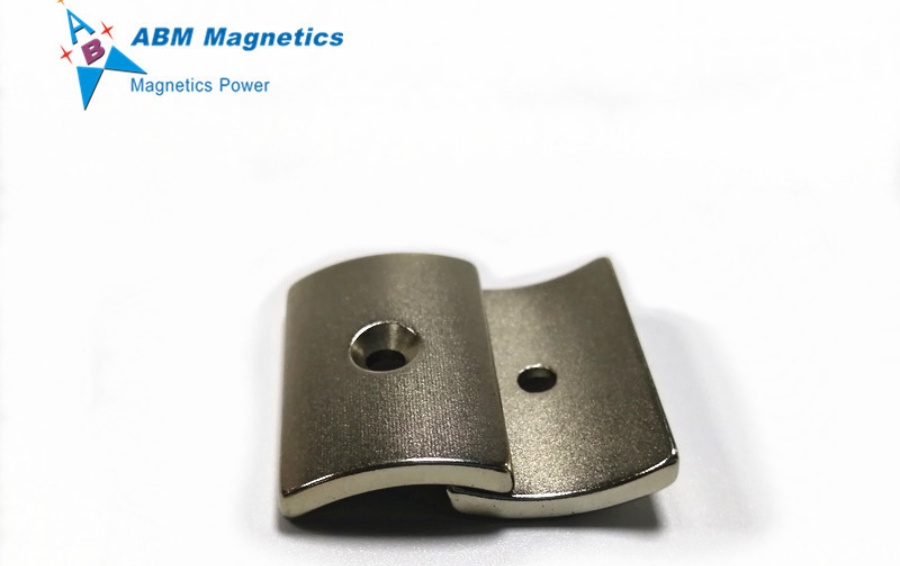

In the field of magnetic materials, high-temperature NdFeB magnets stand out for their excellent performance and wide range of applications, becoming an indispensable and important part of modern industry and science and technology. This article will give a detailed introduction to the performance characteristics, preparation process, application fields and development trends of high-temperature NdFeB magnets.1. Performance characteristicsHigh-temperature NdFeB magnets, as a special type of NdFeB permanent magnet material, have high energy density, high coercivity and excellent temperature characteristics. This magnet can maintain stable magnetic properties in extremely high temperature environments, and its operating temperature range usually exceeds that of traditional NdFeB magnets, up to 200 degrees Celsius, and some special grades such as the AH series can even reach 240 degrees Celsius.The magnetic strength of high-temperature NdFeB magnets is closely related to the ambient temperature. Within the operating temperature range, as the temperature increases, the magnetic force will weaken accordingly, but this weakening is reversible, that is, most of the magnetic force can be restored to its original level after cooling. However, when the temperature exceeds the Curie temperature, the magnet will undergo irreversible demagnetization, so the working environment temperature needs to be strictly controlled in practical applications.2. Preparation processThe preparation process of high-temperature NdFeB magnets is complex and delicate, mainly including raw material preparation, mixing, pressing, sintering, heat treatment and surface treatment. The raw materials mainly include high-purity neodymium, iron and boron elements. The purity of these raw materials must reach more than 99.9% to ensure the quality and performance of the final product.During the mixing process, the proportion of various elements needs to be accurately controlled, because different proportions will have a significant impact on the magnetic properties of the final product. The evenly mixed powder is placed in a pressing mold and pressed by high pressure. The pressed blank is sintered to make the particles fuse with each other to form a dense block. The sintered product also needs to undergo heat treatment processes such as quenching and tempering to further improve its magnetic properties and stability. Finally, in order to improve the corrosion resistance and aesthetics of the product, surface treatments such as electroplating and spraying are also required.3. Application fieldHigh-temperature NdFeB magnets have been widely used in many fields due to their excellent performance and stability. In the electronics industry, it is often used to make key components of high-performance electronic equipment such as speakers, motors, and generators; in the aerospace field, high-temperature NdFeB magnets are used to make precision instruments such as compasses and gyroscopes for navigation systems; in the energy field, it is also used to make cutting-edge technology products such as high-temperature superconducting magnets.In addition, high-temperature NdFeB magnets are also widely used in equipment that converts mechanical energy into electrical energy or electrical energy into mechanical energy, such as receivers, generators, motors, etc. At the same time, based on the principle that magnets repel and attract each other, it is also used to make electromagnets, electromagnetic conveyor belts, magnetic separators and other mechanical equipment.4. Development TrendWith the continuous advancement of science and technology and the increasing demand for high-performance magnetic materials, the preparation process and application fields of high-temperature NdFeB magnets are also constantly expanding. In the future, high-temperature NdFeB magnets will develop in the direction of higher operating temperatures, higher magnetic properties and lower costs. At the same time, with the rapid development of emerging industries such as new energy vehicles and intelligent manufacturing, the application fields of high-temperature NdFeB magnets will be further broadened. As a magnetic material with excellent performance and wide application, high-temperature NdFeB magnets play an important role in modern industry and science and technology. With the continuous advancement of technology and the continuous expansion of application fields, its development prospects will be broader.

As a magnetic material with excellent performance and wide application, high-temperature NdFeB magnets play an important role in modern industry and science and technology. With the continuous advancement of technology and the continuous expansion of application fields, its development prospects will be broader.